Laboratory

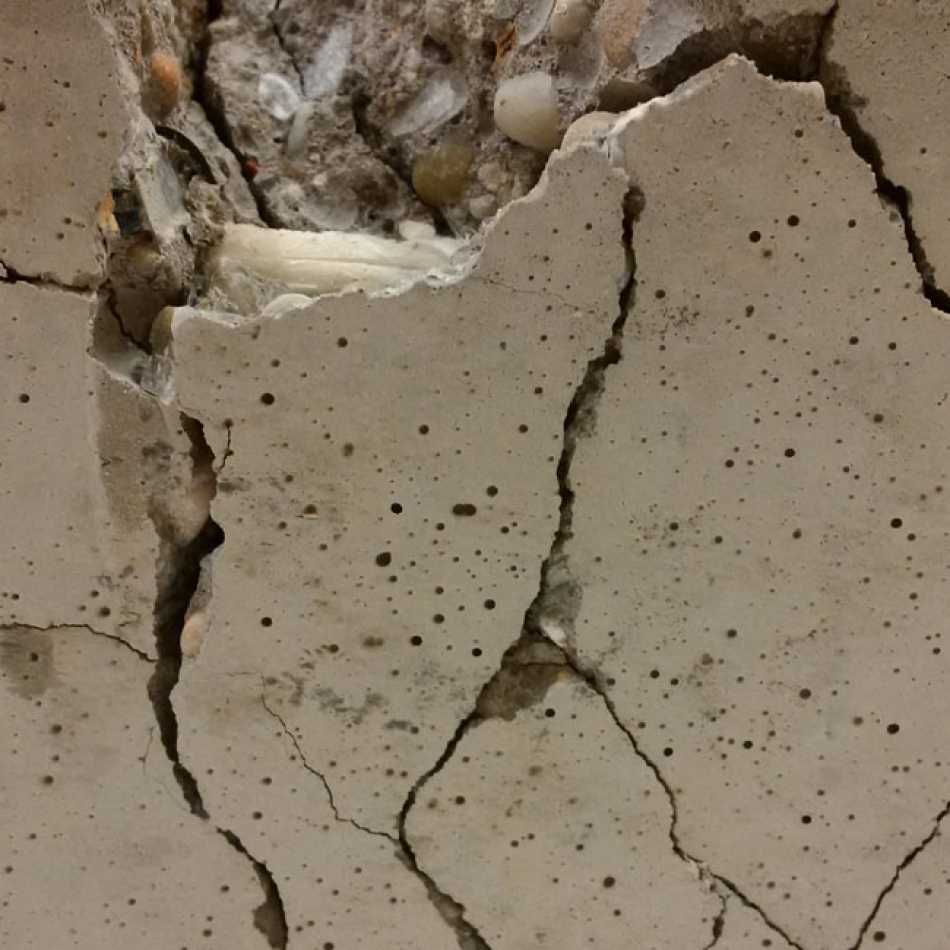

In 2020, JKP Static Ltd. established its own Concrete Laboratory to better meet the growing and complex needs of our clients. The laboratory allows us to stay at the forefront of material research and testing, providing the flexibility to test new materials and continually improve sustainability practices in the construction industry. Having an in-house lab is crucial for us to conduct real-time material validation, ensuring that the designs we produce are based on accurate, up-to-date data.

Our laboratory is accredited according to EN ISO/IEC 17025:2018 standards, which guarantees the highest level of precision, reliability, and quality control in all tests. This accreditation is essential, as it ensures that our methods are consistent with international standards and provides credible, reproducible results for both internal use and external clients.

Key Personnel

| Head of Laboratory: | Tímea Tuza |

| Quality Management: | Dr Peter Karoly Juhasz |

Capabilities

Our in-house lab provides comprehensive testing and research services, enabling:

- Sustainability: Validation of recycled and eco-friendly materials.

- Innovation: Rapid testing of novel designs and construction methods.

- Quality Control: Ensuring materials meet performance standards under various conditions.

Industrial Testing Services

We collaborate with clients across industries to deliver customized testing solutions. Our services include:

- Compliance testing for construction projects.

- Evaluation of innovative materials for market readiness.

- Product development support in partnership with manufacturers.

Research and Development

The laboratory focuses on advanced materials and technologies, including:

- Fibre Reinforced Concrete (FRC)

- Fibre Reinforced Polymer (FRP)

Our state-of-the-art machinery allows us to test:

- Load-bearing capacities of structural elements.

- Flexural and compressive strengths of various concretes.

- Durability under different environmental conditions.