Jointless industrial floors

Jointless concrete floors represent a progressive advancement in industrial flooring technology, eliminating saw-cut joints to enhance structural durability, reduce maintenance requirements, and improve overall usability. These floors address the inherent challenges of traditional methods by offering a seamless solution that minimizes cracking and optimizes performance.

Challenges in Jointless Floor Design

Designing jointless industrial floors is a multifaceted engineering challenge. Unlike conventional saw-cut floors, jointless systems must account for complex interactions between material properties, environmental factors, and applied loads. Key considerations include:

- Differential Shrinkage: Variations across the slab thickness create internal stresses.

- Frictional Forces: Interactions between the floor and sub-base impact stress distribution.

- Live Loads: Diverse and dynamic loads must be accommodated without compromising structural integrity.

Currently, no universal standards exist to guide the determination of slab dimensions, making advanced analytical methods essential for achieving reliable designs.

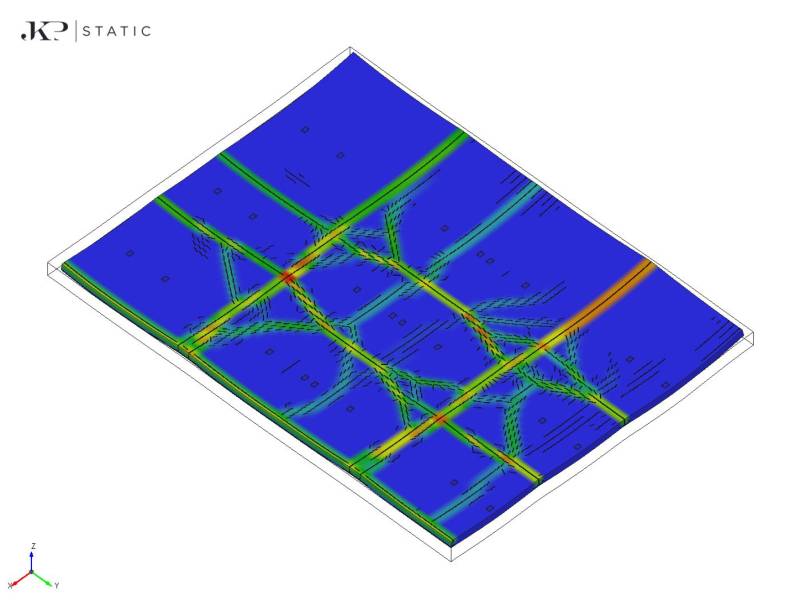

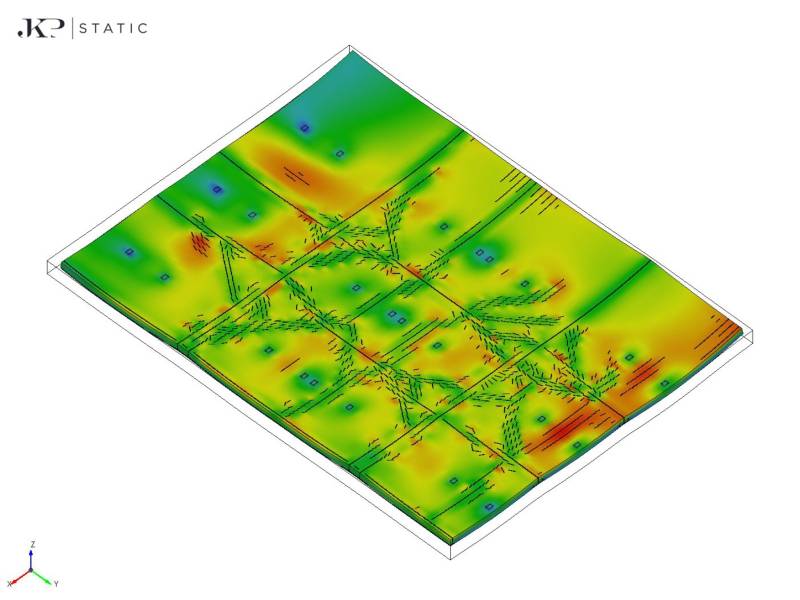

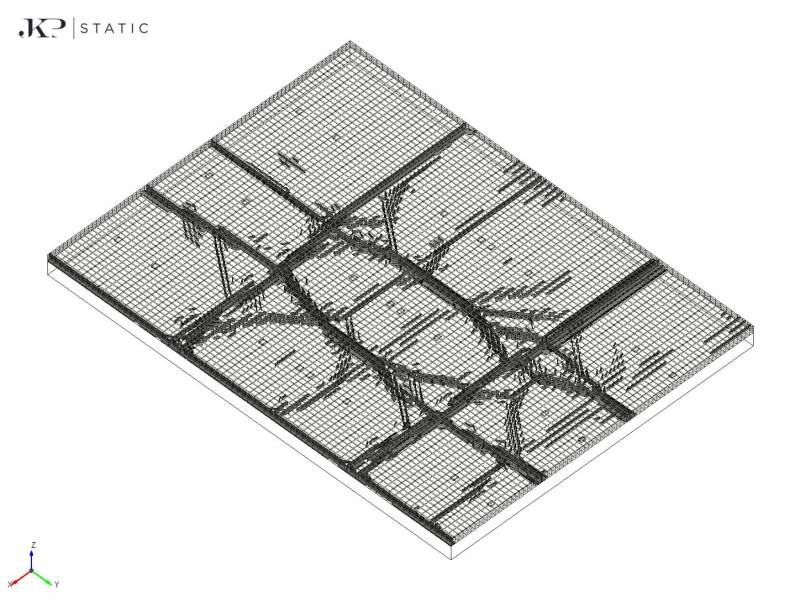

Advanced Finite Element Solutions

To address these complexities, we employ cutting-edge 3D finite element analysis (FEA) tools, such as ATENA. This software integrates advanced material models to accurately simulate the behavior of jointless concrete floors, providing a robust framework for optimizing design and ensuring long-term performance.

Our comprehensive methodology includes:

- Subgrade Modeling: Nonlinear spring models replicate real-world interactions.

- Sub-base Analysis: Linear 3D finite elements ensure precise load distribution.

- Frictional Interfaces: Contact elements manage interactions between the floor and sub-base.

- Concrete Behavior Simulation: Advanced material models capture shrinkage, cracking, and other time-dependent behaviors.

Each model is rigorously calibrated using empirical data from laboratory tests to ensure highly accurate and realistic predictions.

Addressing Time-Dependent Shrinkage

Concrete shrinkage is a critical factor in jointless floor design, evolving over time and influencing structural behavior. Our approach incorporates detailed laboratory testing to calibrate standardized shrinkage functions, enabling precise modeling of time-dependent behavior and ensuring optimal performance throughout the lifecycle of the floor.

Case Study: HelloParks PT2 Warehouse

Our innovative methodology was successfully applied to the HelloParks PT2 warehouse, where we:

- Predicted crack patterns, crack widths, and displacements with precision.

- Delivered an optimized structure compliant with industry guidelines.

- Achieved a cost-effective, durable, and environmentally sustainable solution.

Key Benefits

- Enhanced Durability: Seamless designs reduce crack formation and maintenance needs.

- Sustainability: Low-carbon designs align with environmental objectives.

- Precision Engineering: Advanced simulation ensures compliance with functional and regulatory requirements.

Our work highlights the transformative potential of FEA and material modeling in addressing the complexities of jointless floor design, paving the way for more sustainable and reliable solutions in industrial construction.